Manufacturers and contractors looking for safety and dependability have been turning to electrical lock nut tools in record numbers. These advanced tools are used to connect two threaded parts securely with a locking mechanism, ensuring tamper-proof connections that won’t give way even in demanding applications. Electrical lock nut tools provide reliable and safe fastening solutions that can be depended upon.

A secure nut-and-bolt connection is essential for preventing dangerous electrical shorts or sparks. But traditional fasteners can easily loosen and vibrate free under extreme temperatures or vibrations. That’s why electric lock nut is preferred – it fastens the joint with a locking mechanism that securely holds, no matter the conditions. This higher level of safety and security for electric connections isn’t something to take lightly.

For a reliable secure connection on your electrical system, two types of lock nut tools exist: one-piece and two-piece. One-piece tools provide the simplicity of a single securing device but can prove challenging to detach in the event of corrosion or jamming. On the other hand, two-piece tools call upon a double locking system, yet require a bit more work to install correctly.

Temperamentally effective for general applications, one-piece electrical lock nut tools are built to attach diverse electrical wires, cables, and other components. These instruments are precisely crafted from either steel or brass, adjustable in size to be appropriate with any type of nut. Similarly, they are configured to be utilized with several varieties of thread types, making them a viable tool for a broad range of projects.

Two-piece electrical lock nut tools are widely used in specialty applications, including everything from medical systems to aerospace equipment. Crafted from tough steel, the tool’s dual locking system guarantees a secure connection that won’t loosen or break despite corrosion or jamming. Installation and removal is simplified so you don’t have to worry about a complicated setup or disassembly process.

When it comes to selecting the right tool for electrical lock nuts, the application and environment in which it will be employed should be taken into consideration. For basic tasks, one-piece tools are usually suitable; but for more particular operations, a two-piece version may be the optimal choice for maximum safety. It is vital to select a tool that is tailored for the thread type that will be employed.

When constructing any electrical system, from generators to lightbulbs, having a reliable electrical lock nut tool is essential. It enables secure connections between two threaded elements, providing security and reliability for the entire system. By selecting the proper tool for the job, manufacturers and contractors can trust that their connections are sturdy and dependable.

Unlocking the Mysteries of Electric Lock Nut Tools: An All-Encompassing Guide

If you are an electrician or handyman looking for a safe way to secure any electrical connections, then an electrical lock nut tool is an invaluable item. Used often to clamp down wires and prevent any backlash or looseness, there are a number of distinct types of these tools. To help you make the best choice for your projects, we have compiled the most important details to learn about electrical lock nuts and their uses.

When it comes to lock nut tools, there are two main varieties. The first is a kind of standard flanged nut tool, which is especially handy for use with screw-type fastenings, such as screws, nuts, and bolts. The tool consists of three parts – an outer body made of metal with a flanged head at one end, a nut which needs to be placed over the fastener, and lastly, the threaded fastener itself. This design allows the body to be securely tightened down, thereby locking the fastener in place. This type of tool is most effective when employed with small fasteners such as those employed for electronic components, wires, and cables.

A specialized lock nut tool is developed for fasteners of a larger diameter, or the ones often found in industrial operations. It is composed of two components: a metal body equipped with a threaded head at one end, and a nut that is to be placed over the fastener. After the nut has been situated, the body must be tightened to ensure robust and secure connection. This type of equipment is ideal for heavy-duty applications that involve larger-sized fasteners.

After covering the two principal classifications of electric lock nut tools, it’s time to delve into how they are employed. Firstly, the required nut must be set over the fastener. Then, the casing of the lock nut apparatus should be tightened to keep the nut and the fastener firmly in position which will confirm a reliable bond.

When utilizing electrical lock nut apparatuses, it is paramount to bear in mind the necessity of the nut and fastener being properly harmonised. For instance, if a traditional flanged nut were to be used with an expansive-diameter screw, it would fail to provide a trustworthy joint. Furthermore, it is essential to ascertain that the nut and fastener are free from obstructions and absolutely tidy before making use of the lock nut tool.

Specialized lock nut tools are pricier than the standard type, but offer more dependable fastening – especially for applications in automotive and HVAC contexts. These distinct instruments are engineered for a particular set of duties and offer enhanced, reliable protection.

To guarantee safe operation while using electrical lock nut tools, it is absolutely essential to comply with the manufacturer’s guidance. Utilizing unsuitable instruments can pose a hazard since the tension of the nut may be inadequate. Moreover, taking particular care not to overtighten the nut and fastener is crucial to avoiding breakage and malfunction.

All in all, electricians and hobbyists can’t manage without electrical lock nuts. The tools are used to guarantee that electrical connections, like cables, remain immovably fastened and don’t become detached. Every single one of these tools drops inside two classifications – regular flanges and those with a unique purpose. When dealing with them, it’s critical to make certain the nut and the fastener match impeccably, are spotless, and don’t contain debris. Moreover, the creator’s directions must be followed closely and the right tools ought to be utilized for the assignment. With the correct strategies for use and information on hand, these nuts can move toward becoming dependable safety measures when it comes to electrically connecting two parts.

Related Product

High Speed 12V Power Tools With Lithium Battery

Product Description Power Source Electric Biggest drill hole 16mm Customized support OEM Application Industry Dimensions 32mm Hammering frequency 6200 Frequency 6200 MOQ 1PCS Max. […]

High Quality Multifunction Battery Powered Drill For Sale

Warranty 1 years Voltage 21V Place of Origin China Brand Name MSK Model Number MSK-PT Power Source LI-ION BATTERY No-Load Speed 1350prm Drilling Diameter 10mm Features 1. Strong to […]

Miter Saw Trim Panel Machine

Product Information Brand MSK Maximum Processing Thickness 80 (mm) Type Panel Saw Maximum Processing Width 1250 (mm) Forms Of Work Fully Automatic Total Weight 600 (kg) Rate […]

Power Tools Lithium Battery Power Drill Impact Drill

Product Information Brand MSK Power Type Rechargeable – Lithium Battery Technology Drill Holding Method Drill Chuck Forward And Reverse Direction About Scope Of Applic […]

Belt Machine Floor Sander

Product Information Brand MSK Sandpaper Size 110*100 Scope Of Application Woodworking, Sheet Metal Putty, Facade, Metal Derusting And Polishing Appendix Export Standard, Eur […]

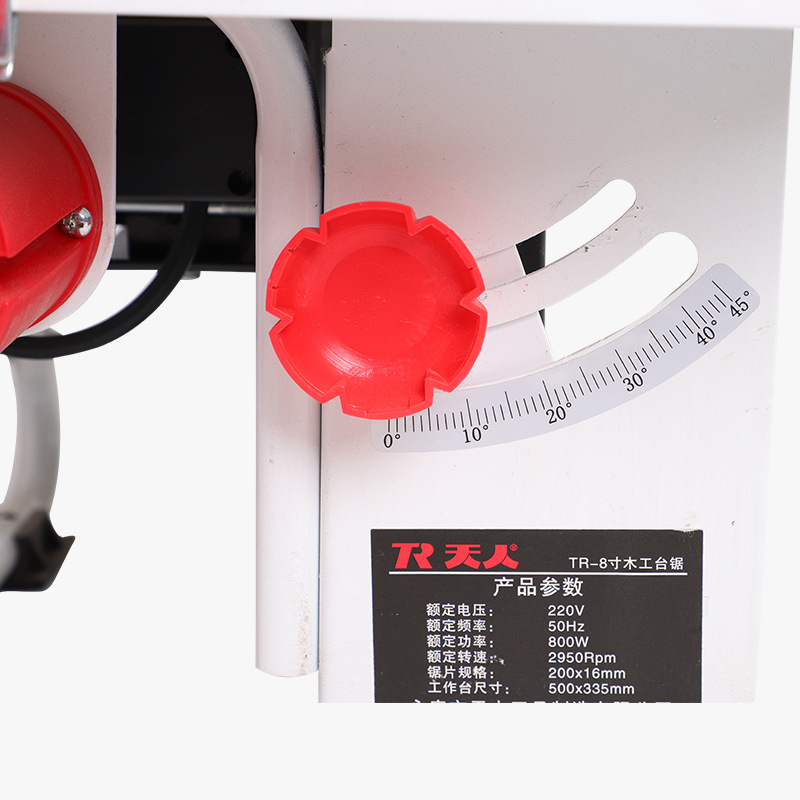

Woodworking Tools Woodworking Table Saw

Product Information Origin MSK Rated Voltage 220V Type Table Saw Scope Of Application Home Renovation Cutting Depth 45-27 (mm) Power Type AC Power Rated Input Power 800 (W) […]

Home Cutting Machine Hand Grinder Power Tools Grinder

Product Information Brand MSK Model Electric Angle Grinder Scope Of Application Cutting, Grinding Appendix Wrench, Carbon Brush Rated Voltage Range AC Single-Phase And DC 50 […]

Factory Wholesale High Pressure Water Gun Wireless Lithium Battery Car Wash Gun Charging Portable Car Wash Machine Brush Car Wash Machine

Product Information Brand MSK Work Pressure 30bar Material ABS Flow 3L/min Outlet Pipe Length 5 Meters Weight 2.5kg Power Cord Length Charger 1 Meter Power 180W/360W Power S […]

Wookworking Tool Electric Hand Planer

Product Information Brand MSK Power Type AC Power Power Cord Length 1.8 Rated Voltage Range AC Single-Phase And DC 50V Above 250V And Below Scope Of Application Carpentry Vo […]

Battery-powered Cordless Chainsaws

Product Information Brand MSK Voltage Twenty Four Battery Power 2000 Standard Accessories Guide Chain Scope Of Application Pruning, Logging, Cutting Power Type Rechargeable […]

Post time: 2023-07-06