A tool aiming to guarantee a secure connection between automotive electrical connector terminals and the wires they are connected to is the automotive electrical connector terminal crimping tool. This specialized tool consistently creates a resilient crimp, ensuring these crucial connections stay unbroken and properly functioning.

When it comes to attaching automotive electrical connectors, the type of crimping tool you use is dependent on the terminal you are working with. If you’re tackling a spade terminal, the two most popular options are a manual crimping tool or a pneumatic alternative. The former of the two is operated by hand, while the latter requires air pressure to work its magic. Whatever one you decide to go for, these tools guarantee an efficient terminal-crimping experience.

When relying on a manual crimping tool to work with terminals, it is of utmost importance to select jaws of the right size. Too thin jaws may compromise their grip over the terminal, while overly thick jaws may not be suitable for avoiding damage to the terminal.

Prior to crimping the terminal, making sure that the jaw positions are accurate is critical. Failing to do this properly could lead to an imperfect crimp and a sorry connection.

The jaws of the tool should be adjusted to fit the size and alignment of the terminal before the wire is inserted. Push the wire in firmly, all the way until resistance is felt. Only then, clamp the pliers around both the wire and terminal to secure them in place.

The amount of tension necessary for the crimping process is dependent upon the nature of the terminal’s material; a terminal built from something supple would necessitate less force to be applied.

Once the tool has been locked around the wire and terminal, give it a good squeeze until its handles meet. This will cause the tool to crimp the terminal tightly to the wire.

Once the terminal grips the wire securely, any extra wire should be snipped off. This can be done with either a pair of wire cutters or a precise blade.

To ensure the integrity of the automobile’s electrical system, it is necessary to perform an initial analysis. This can be done by gently introducing a low-level voltage current to the joint and gauging the flow for steadiness.

If you’re tackling highly durable materials, then it might be time to switch to a pneumatic crimping tool. This device operates on the same general principles as a manual crimping tool, but applies greater pressure to securely crimp the tough materials.

An air compressor is essential in order to use a pneumatic crimping tool, delivering enough air power to run the machine. Additionally, this contraption must feature a regulator to keep the force being applied to the tool well within acceptable levels.

Although the cost of pneumatic crimping tools may be greater than manual alternatives, such tools will provide a safeguard against damaging wire terminals during crimping operations.

To guarantee a secure connection, using a crimping tool requires precision, rendering the following of the instructions supplied imperative. Doing so will ensure that the crimp is executed properly.

Related Product

High Speed 12V Power Tools With Lithium Battery

Product Description Power Source Electric Biggest drill hole 16mm Customized support OEM Application Industry Dimensions 32mm Hammering frequency 6200 Frequency 6200 MOQ 1PCS Max. […]

High Quality Multifunction Battery Powered Drill For Sale

Warranty 1 years Voltage 21V Place of Origin China Brand Name MSK Model Number MSK-PT Power Source LI-ION BATTERY No-Load Speed 1350prm Drilling Diameter 10mm Features 1. Strong to […]

Miter Saw Trim Panel Machine

Product Information Brand MSK Maximum Processing Thickness 80 (mm) Type Panel Saw Maximum Processing Width 1250 (mm) Forms Of Work Fully Automatic Total Weight 600 (kg) Rate […]

Power Tools Lithium Battery Power Drill Impact Drill

Product Information Brand MSK Power Type Rechargeable – Lithium Battery Technology Drill Holding Method Drill Chuck Forward And Reverse Direction About Scope Of Applic […]

Belt Machine Floor Sander

Product Information Brand MSK Sandpaper Size 110*100 Scope Of Application Woodworking, Sheet Metal Putty, Facade, Metal Derusting And Polishing Appendix Export Standard, Eur […]

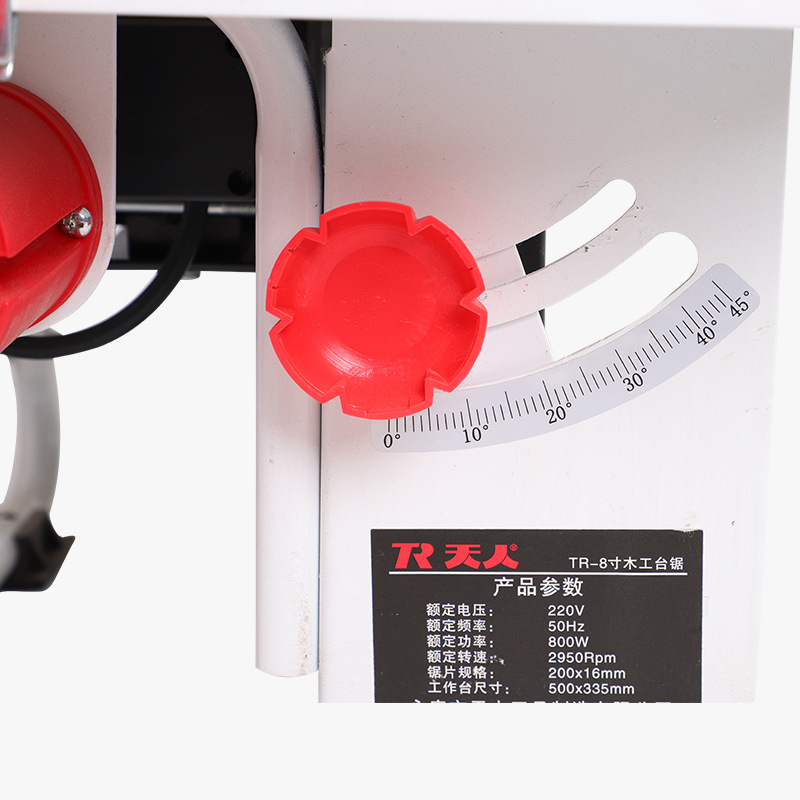

Woodworking Tools Woodworking Table Saw

Product Information Origin MSK Rated Voltage 220V Type Table Saw Scope Of Application Home Renovation Cutting Depth 45-27 (mm) Power Type AC Power Rated Input Power 800 (W) […]

Home Cutting Machine Hand Grinder Power Tools Grinder

Product Information Brand MSK Model Electric Angle Grinder Scope Of Application Cutting, Grinding Appendix Wrench, Carbon Brush Rated Voltage Range AC Single-Phase And DC 50 […]

Factory Wholesale High Pressure Water Gun Wireless Lithium Battery Car Wash Gun Charging Portable Car Wash Machine Brush Car Wash Machine

Product Information Brand MSK Work Pressure 30bar Material ABS Flow 3L/min Outlet Pipe Length 5 Meters Weight 2.5kg Power Cord Length Charger 1 Meter Power 180W/360W Power S […]

Wookworking Tool Electric Hand Planer

Product Information Brand MSK Power Type AC Power Power Cord Length 1.8 Rated Voltage Range AC Single-Phase And DC 50V Above 250V And Below Scope Of Application Carpentry Vo […]

Battery-powered Cordless Chainsaws

Product Information Brand MSK Voltage Twenty Four Battery Power 2000 Standard Accessories Guide Chain Scope Of Application Pruning, Logging, Cutting Power Type Rechargeable […]

Post time: 2023-06-21