With their myriad applications in industries ranging from construction to engineering, electric tools have become the cornerstone of modern-day productivity. Despite their convenience, however, they are prone to technical difficulties and require proper handling and upkeep. Fortunately, electric tool maintenance need not be a hassle; armed with the appropriate tools and knowledge, anyone can easily undertake the task with nominal effort.

Electrical tool repair begins with discovering the source of the malfunction. In many cases, it is possible to self-diagnose by inspecting the tool for worn out components, unfastened connections, or out-of-date lubrication. If the tool does not function whatsoever, taking it to a service expert may be necessary.

When you are aware of what needs to be fixed, it’s time to begin the remedial process. Ensure you have the requisite tools and supplies for the task at hand. For corded equipment, you’ll demand a screwdriver and electrical tape. On the other hand, if it is cordless, a set of wrenches and a soldering iron are needed. You may also need additional components such as covers for switches, bushings, and torsion springs.

To start the repair process, begin by making sure you have all the necessary items for the job. Then, disconnect the tool from its power source or remove the batteries. Carefully take apart each component, taking care to loosen screws, clips, and other fasteners if needed. Once everything has been taken apart, start evaluating each piece to figure out what went wrong and how to fix it.

When it’s time to find that replacement part, make sure it’s the perfect fit. It’s essential that you pick a part that meshes with the manufacturer’s requirements. If you are uncertain which one is needed, referencing the owner’s manual or contacting the maker are both viable options.

After the swapped part is in its place, the tool needs to be reassembled. Here, it’s essential to oil up the elements that move and confirm that each piece is securely connected. When the tool is completely put back together, you can check its performance to validate that it’s functioning appropriately.

If you find yourself in a bind with your electric tool and unsure of how to fix it, seeking help from a professional service center might be your best bet. There are many centers specialized in electric tool repair available that can likely diagnose and take care of the problem for you hassle-free.

Electric tool repair can be a straightforward endeavor once the correct measures have been implemented. It’s essential to stay safe and protected while taking on such a task, so always disconnect the cord or remove the battery before commencing the procedure. In addition, be sure to wear the proper attire and eye protection, and gather all relevant instruments and components. If you are ever uncertain about particular elements of the process, refer to the accompanying manual or reach out to the manufacturer for help. Gathering the pertinent information and organizing the necessary materials will help you repair your electric tool yourself in no time.

Electric tools make modern workplaces what they are: efficient and convenient. However, their complexity can cause them to malfunction, resulting in the need for repairs. This article dives into the basics of electric tool repair, examining the process and how to go about it.

The journey of electric tool repair begins with pinpointing the problem. The manual that typically comes along with these tools generally has a troubleshooting guide which can help find the root of the issue. Should the problem be absent from the manual, an adept technician can typically identify it by simply conducting a visual examination of the tool.

Once the issue is uncovered, it’s time to pinpoint the required pieces. If certain components for electrically operated tools aren’t accessible at a nearby shop, then ordering them virtually may be inescapable. Making sure the parts are compatible with the tool’s make and model, and several other essential safety and quality requisites must be taken into account as well.

Once the needed components have been acquired, the ability to repair is at your fingertips. Thoroughly read through all instructions and take it slow, one step at a time. Certain repairs may require a higher level of expertise, so it would be wise to hire a certified specialist.

Ensuring absolute safety when repairing should be top priority- turn off the tool and adhere to all precautionary measures. Additionally, donning protective eyewear and hand coverings will help to shield yourself from potential electricity hazards.

After the broken component is fixed, it is essential to ensure the device’s functionality. If the machine’s performance is unsatisfactory, contact a qualified technician for further aid.

Troubleshooting and fixing electric tools can be a tricky process. However, if undertaken carefully, it can be achieved easily and promptly. It is vital to employ the right components and remember safety regulations. Knowledge coupled with the right time and equipment aid in making electric tool fixing a breeze.

Related Product

High Speed 12V Power Tools With Lithium Battery

Product Description Power Source Electric Biggest drill hole 16mm Customized support OEM Application Industry Dimensions 32mm Hammering frequency 6200 Frequency 6200 MOQ 1PCS Max. […]

High Quality Multifunction Battery Powered Drill For Sale

Warranty 1 years Voltage 21V Place of Origin China Brand Name MSK Model Number MSK-PT Power Source LI-ION BATTERY No-Load Speed 1350prm Drilling Diameter 10mm Features 1. Strong to […]

Miter Saw Trim Panel Machine

Product Information Brand MSK Maximum Processing Thickness 80 (mm) Type Panel Saw Maximum Processing Width 1250 (mm) Forms Of Work Fully Automatic Total Weight 600 (kg) Rate […]

Power Tools Lithium Battery Power Drill Impact Drill

Product Information Brand MSK Power Type Rechargeable – Lithium Battery Technology Drill Holding Method Drill Chuck Forward And Reverse Direction About Scope Of Applic […]

Belt Machine Floor Sander

Product Information Brand MSK Sandpaper Size 110*100 Scope Of Application Woodworking, Sheet Metal Putty, Facade, Metal Derusting And Polishing Appendix Export Standard, Eur […]

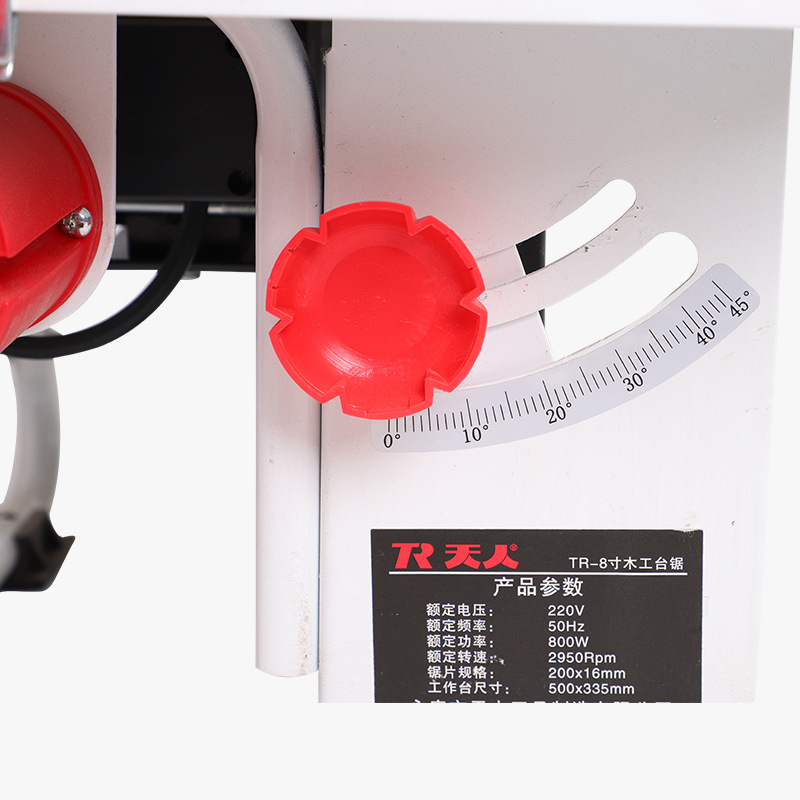

Woodworking Tools Woodworking Table Saw

Product Information Origin MSK Rated Voltage 220V Type Table Saw Scope Of Application Home Renovation Cutting Depth 45-27 (mm) Power Type AC Power Rated Input Power 800 (W) […]

Home Cutting Machine Hand Grinder Power Tools Grinder

Product Information Brand MSK Model Electric Angle Grinder Scope Of Application Cutting, Grinding Appendix Wrench, Carbon Brush Rated Voltage Range AC Single-Phase And DC 50 […]

Factory Wholesale High Pressure Water Gun Wireless Lithium Battery Car Wash Gun Charging Portable Car Wash Machine Brush Car Wash Machine

Product Information Brand MSK Work Pressure 30bar Material ABS Flow 3L/min Outlet Pipe Length 5 Meters Weight 2.5kg Power Cord Length Charger 1 Meter Power 180W/360W Power S […]

Wookworking Tool Electric Hand Planer

Product Information Brand MSK Power Type AC Power Power Cord Length 1.8 Rated Voltage Range AC Single-Phase And DC 50V Above 250V And Below Scope Of Application Carpentry Vo […]

Battery-powered Cordless Chainsaws

Product Information Brand MSK Voltage Twenty Four Battery Power 2000 Standard Accessories Guide Chain Scope Of Application Pruning, Logging, Cutting Power Type Rechargeable […]

Post time: 2023-07-07