Electrical technicians and electricians alike know the importance of electrical cable bending tools. To create the perfect shape in the cables without compromising the insulation, or conductor of course, these incredibly versatile mechanisms come in all forms and sizes. Made from various materials, they prove to be a handy tool for a wide range of applications.

To get the job done safely and correctly when wiring up electrical cables, it is crucial to ensure that all bends are tight and neat. When not properly secured, the cable can short circuit, possibly leading to equipment destruction, and endangering any nearby people. To achieve precise and measured bends each time, electrical cable bending tools are essential.

A plethora of bending tools exist, varying from the cost-effective manual hand tools to the complex motorized ones. The simpler manual tools are often preferred as they are sufficient to make right-angle, offset and U-shaped bends.

If you’re looking for precision and control, invest in a powered motorized tool. Particularly useful for aircraft wiring, where complex bends are involved, they come with the advantage of being computer-controlled. Whether you choose manual or programmed operation, with the simple press of a button you can count on consistently accurate bends.

It is essential to determine the type of cable when picking an electrical cable bending tool. Manual tools are preferred when dealing with copper cables, whereas more robust motorized solutions are required to successfully bend aluminum cables.

The type and size of the bending tool needed for a job depend on its use. For projects like telephone wiring, a more petite tool is necessary, while a larger one is ideal for industrial wiring. Also critical is the type of insulation that is utilized; distinct tools must be used to ensure the insulation doesn’t break during the bending process.

Price must always be considered when selecting a tool. However, manual tools tend to be more affordable and, while they are capable of getting the job done, powered motorized tools often provide more reliable accuracy and control for more precise operations.

Electrical cable bending tools are paramount for any electrician or technician manipulating electrical cables; they give the precision and command demanded for tight, clean bends that prevent shorting out and destroying equipment. When picking an electrical cable bending tool, factors like the wire’s kind, tool sizing, insulation, and expense may need to be evaluated. By taking into account the appropriate elements, electricians and technicians can guarantee that their cables are bent with optimal accuracy.

Any electrician or technician knows that electrical cable bending tools are a must-have for accurate and precise bends in electrical cables. Without them, cumbersome and time-consuming options are all that remains. Fortunately, these tools simplify the installation of electrical systems, allowing bends to be crafted quickly and accurately.

When seeking out the ideal electrical cables for any application, a range of bending tools can be employed for maximum efficiency. Primarily, these tools are cable benders which permit the formation of curves in the cable, cable strippers for removing insulation from the wire, and cable cutters to divide the cords into the desired lengths. Each of these implements can be employed depending on the specific needs of a project.

Steel cable benders exist in a variety of different sizes, for curves of varying tightness depending on the size of the cable. These benders come as both hand-held and stationary models, each equipped with a length stop to ensure that the bends are formatted to the precise angle desired. The type of cable being worked on is also a factor to consider when selecting an appropriate bender.

Cable strippers, whether hand-held or stationary, are needed for the task of revealing the conductor inside insulated cables. Depending on the size of the cable, either a hand-held or stationary model will be suitable. These devices have blades that can dexterously slice away insulation layers without damaging the cable interior. The depth of the insulation can also be taken into account when adjusting these blades to attain the desired results.

Utilized for slicing stubborn cables into the ideal length, cable cutters can come in both stationary and handheld forms. The portable small-scale cutters are typically employed for trimming diminutive cables, while larger stationary tools can be the better option for bigger wires. With adjustable blades and a precision cutting edge, these cutters guarantee accurate tidy cuts, regardless of cable size.

Regardless of the job requirements, picking the ideal electrical cable bending tool is paramount. High-quality tools which are compatible with the cable in question are essential for a successful task completion. Ensuring the cable is installed correctly is a must for achieving satisfaction with the results of your work.

To ensure that electrical cable bending operations are completed carefully and correctly, it is paramount to comply with the manufacturer’s instructions and safety guidelines. Alongside this, proper upkeep of the tool is also essential in order to keep it functioning efficiently for the long-term. Regular maintenance will safeguard the tool’s optimal working condition and amplify its lifecycle.

Working with electrical cable requires precision, and the job can be laborious without the right tools. In a way, electrical bending tools are the electrician’s saving grace; they make the task of bending cable far more efficient and accurate, providing a surefire way of getting the job done correctly.

Related Product

High Speed 12V Power Tools With Lithium Battery

Product Description Power Source Electric Biggest drill hole 16mm Customized support OEM Application Industry Dimensions 32mm Hammering frequency 6200 Frequency 6200 MOQ 1PCS Max. […]

High Quality Multifunction Battery Powered Drill For Sale

Warranty 1 years Voltage 21V Place of Origin China Brand Name MSK Model Number MSK-PT Power Source LI-ION BATTERY No-Load Speed 1350prm Drilling Diameter 10mm Features 1. Strong to […]

Miter Saw Trim Panel Machine

Product Information Brand MSK Maximum Processing Thickness 80 (mm) Type Panel Saw Maximum Processing Width 1250 (mm) Forms Of Work Fully Automatic Total Weight 600 (kg) Rate […]

Power Tools Lithium Battery Power Drill Impact Drill

Product Information Brand MSK Power Type Rechargeable – Lithium Battery Technology Drill Holding Method Drill Chuck Forward And Reverse Direction About Scope Of Applic […]

Belt Machine Floor Sander

Product Information Brand MSK Sandpaper Size 110*100 Scope Of Application Woodworking, Sheet Metal Putty, Facade, Metal Derusting And Polishing Appendix Export Standard, Eur […]

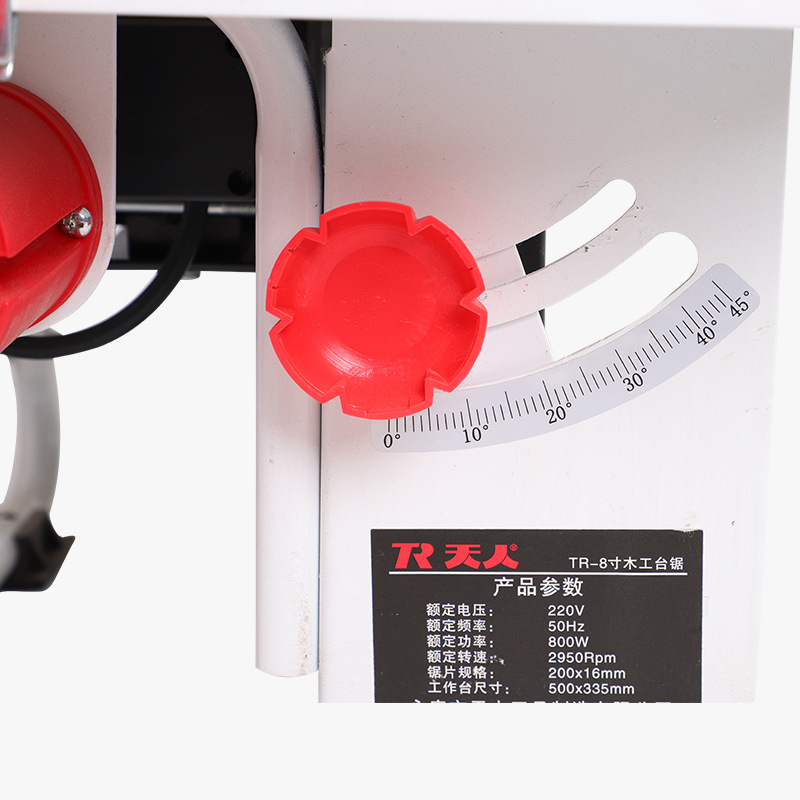

Woodworking Tools Woodworking Table Saw

Product Information Origin MSK Rated Voltage 220V Type Table Saw Scope Of Application Home Renovation Cutting Depth 45-27 (mm) Power Type AC Power Rated Input Power 800 (W) […]

Home Cutting Machine Hand Grinder Power Tools Grinder

Product Information Brand MSK Model Electric Angle Grinder Scope Of Application Cutting, Grinding Appendix Wrench, Carbon Brush Rated Voltage Range AC Single-Phase And DC 50 […]

Factory Wholesale High Pressure Water Gun Wireless Lithium Battery Car Wash Gun Charging Portable Car Wash Machine Brush Car Wash Machine

Product Information Brand MSK Work Pressure 30bar Material ABS Flow 3L/min Outlet Pipe Length 5 Meters Weight 2.5kg Power Cord Length Charger 1 Meter Power 180W/360W Power S […]

Wookworking Tool Electric Hand Planer

Product Information Brand MSK Power Type AC Power Power Cord Length 1.8 Rated Voltage Range AC Single-Phase And DC 50V Above 250V And Below Scope Of Application Carpentry Vo […]

Battery-powered Cordless Chainsaws

Product Information Brand MSK Voltage Twenty Four Battery Power 2000 Standard Accessories Guide Chain Scope Of Application Pruning, Logging, Cutting Power Type Rechargeable […]

Post time: 2023-07-06