To boost electrical conductance between two pieces of hardware, electrical contact burnishers are employed. From the auto industry to aerospace, medical, and electrics, this tool is invaluable for cleaning and polishing connectors, allowing them to perform optimally. Electrical contact burnishers make it possible to obtain a seamless transfer of electrical currents, gratifying users with a reliably secure connection.

By applying pressure to the contact surface, an electrical contact burnishing tool can help to facilitate a more efficient electrical connection between two components. This burnishing process works to smooth down any small imperfections on the contact which could be obstructing a secure connection. It also eliminates any oxidation or debris that may have accumulated over time, enabling a higher quality connection to be established.

The electrical contact burnishing tool is quite flexible in its application; it can be utilized to care for and refine electrical contacts used in automotive and aerospace engineering, medical and electrical operations, as well as consumer and industrial electronics. This tool provides an effective means of cleaning and preserving electrical contacts found in a wide range of fields.

Anyone in the electrical and electronics industry looking for a cost-effective and dependable solution for the enhancement of electrical connections should consider the use of an electrical contact burnishing tool. It ensures a safe and reliable way to upgrade the connection between two components, thereby facilitating better performance.

Wielding immense power and simple operation, the electrical contact burnishing tool is the perfect no-brainer for any job. This motorized marvel is connected to a brush or wheel that can deliver the necessary pressure to the contact surface, resulting in a smooth, clean finish. No prior knowledge or training needed – the tool takes care of it all!

From diminutive micro-components to gigantic industrial elements, the burnishing tool is ideal for conditioning and burnishing contacts of all sizes. Offered in a range of shapes and materials – from stainless steel to brass – this tool is flexible enough to get the job done.

Failure to adhere to safety protocols and equip the right protective gear when operating an electrical contact burnishing tool can be hazardous. Equally as detrimental is utilizing the wrong brush or wheel as it can quickly cause damage to the contact surface. To ensure proper and efficient usage of the tool, it is highly recommended that you firmly follow manufacturer instructions.

Those working in the electrical or electronics sectors will find the electrical contact burnishing tool a necessary piece of equipment. This cost-effective device can efficiently condition and clean electrical contacts, thus improving their function and enhancing their connection with other components. This compact yet versatile tool provides an effortless, secure means of elevating the performance of electrical parts.

Any electrical service or maintenance team would benefit greatly from access to electrical contact burnishing tools. These efficient tools can be used to restore contacts to pristine condition, resulting in improved performance and dependability. Furthermore, they will guarantee that electrical connections remain stable and well-protected from corrosion.

To help keep the electrical performance of contacts running at peak levels, electrical contact burnishing tools are used. Providing an efficient abrasive cleansing process, these tools spin a series of abrasive contact surfaces in a circular pattern to break down any corrosion that has built up on the electrical contacts. Doing so eliminates the risks of arcing and sparking, which can lead to electrical shorts, and ensures that contacts remain corrosion-free.

To get the best results, utilizing an electrical contact burnishing tool is a straightforward process. Start by clearing the tool’s contact surfaces with an applicable cleaner or solvent. Place the tool’s contacts between their respective surfaces then activate the device. To eliminate corrosion and debris, back and forth movements of the instrument should be performed numerous times until a contamination-free finish is achieved between the contact surfaces.

Before reassembly, the power source should be disengaged from the burnishing tool. Then, assess the contacts for any remaining residue or dirt – they should appear clean and spotless if proper cleaning was done.

To optimise performance while reducing costs, burnishing tools are the ideal solution for keeping electrical contacts in working condition. Their ease of use and low upkeep make them a practical addition to any toolkit and they have been designed to be used on any type of contact – from miniature to heavy-duty industrial.

Electrical service and maintenance teams greatly benefit from employing burnishing tools into their arsenal of materials, yet such use must be done with due care. The manufacturer’s safety instructions should be strictly adhered to and protective apparel, like protective eyewear and gloves, should be worn to avoid any accidental contact with the contact surfaces. Furthermore, these same contact surfaces must undergo regular examination for signs of damage and need to be replaced as soon as any wear and tear is identified.

Electrical contact burnishing tools are an undeniably valuable resource for any electrical services or upkeep group. Optimized to fix and protect electrical contacts from corrosion and sparks, these tools simplify the process and come with a low maintenance and cost-friendly tag. Restoring contacts back to their original state, they are an effective way of sprucing up performance while saving time and effort.

Related Product

High Speed 12V Power Tools With Lithium Battery

Product Description Power Source Electric Biggest drill hole 16mm Customized support OEM Application Industry Dimensions 32mm Hammering frequency 6200 Frequency 6200 MOQ 1PCS Max. […]

High Quality Multifunction Battery Powered Drill For Sale

Warranty 1 years Voltage 21V Place of Origin China Brand Name MSK Model Number MSK-PT Power Source LI-ION BATTERY No-Load Speed 1350prm Drilling Diameter 10mm Features 1. Strong to […]

Miter Saw Trim Panel Machine

Product Information Brand MSK Maximum Processing Thickness 80 (mm) Type Panel Saw Maximum Processing Width 1250 (mm) Forms Of Work Fully Automatic Total Weight 600 (kg) Rate […]

Power Tools Lithium Battery Power Drill Impact Drill

Product Information Brand MSK Power Type Rechargeable – Lithium Battery Technology Drill Holding Method Drill Chuck Forward And Reverse Direction About Scope Of Applic […]

Belt Machine Floor Sander

Product Information Brand MSK Sandpaper Size 110*100 Scope Of Application Woodworking, Sheet Metal Putty, Facade, Metal Derusting And Polishing Appendix Export Standard, Eur […]

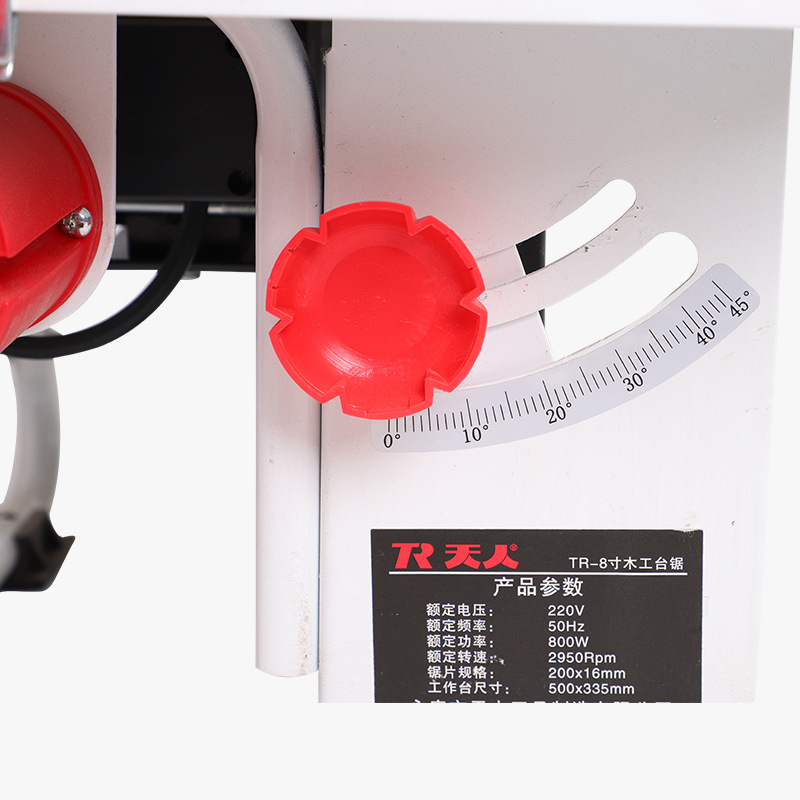

Woodworking Tools Woodworking Table Saw

Product Information Origin MSK Rated Voltage 220V Type Table Saw Scope Of Application Home Renovation Cutting Depth 45-27 (mm) Power Type AC Power Rated Input Power 800 (W) […]

Home Cutting Machine Hand Grinder Power Tools Grinder

Product Information Brand MSK Model Electric Angle Grinder Scope Of Application Cutting, Grinding Appendix Wrench, Carbon Brush Rated Voltage Range AC Single-Phase And DC 50 […]

Factory Wholesale High Pressure Water Gun Wireless Lithium Battery Car Wash Gun Charging Portable Car Wash Machine Brush Car Wash Machine

Product Information Brand MSK Work Pressure 30bar Material ABS Flow 3L/min Outlet Pipe Length 5 Meters Weight 2.5kg Power Cord Length Charger 1 Meter Power 180W/360W Power S […]

Wookworking Tool Electric Hand Planer

Product Information Brand MSK Power Type AC Power Power Cord Length 1.8 Rated Voltage Range AC Single-Phase And DC 50V Above 250V And Below Scope Of Application Carpentry Vo […]

Battery-powered Cordless Chainsaws

Product Information Brand MSK Voltage Twenty Four Battery Power 2000 Standard Accessories Guide Chain Scope Of Application Pruning, Logging, Cutting Power Type Rechargeable […]

Post time: 2023-07-06