For a reliable connection, stranded wires are affixed with a small metal sleeve known as an electrical ferrule. This is achieved using a specialized hand tool, which compresses the ferrule tightly around the wire.

Different metal materials such as copper, aluminum, and stainless steel are used to craft a variety of sizes in ferrules. The size of a ferrule should be selected with utmost care, based on the gauge of the wire. To complete the application correctly, it is imperative to choose an appropriate ferrule size and material.

When selecting a crimping tool, it is paramount to consider the size of the jaws to ensure they can compress the connection securely. A range of sizes and styles are available to suit all needs.

For those looking for crimping tools, there are two varieties to choose from – manual and hydraulic. Manual tools come with a more affordable price tag but require heightened effort to operate, whereas the more expensive hydraulic version is designed to be managed utilizing minimal force.

To ensure an efficient and flawless crimp, it is essential to adhere to the manufacturer’s directives when utilizing any man-powered or hydraulically powered crimping apparatus. This will guarantee that the ferrule is tightly secured onto the cord.

After securing the ferrule onto the wire, it is critical to take a look at the integrity of the junction. Look closely to make certain that the ferrule has been completely seated on the wire with no spaces between them. If there are any spaces, the connection will not be secure and may in turn lead to an electrical malfunction.

Once the connection is examined and validated, it is essential to safeguard it from rusting. A thin coating of grease can be spread across the connection to help guard it from atmospheric conditions.

Electrical connections need to be dependable and secure, and using the correct ferrules and crimping items alongside the proper assembling steps will guarantee that.

Related Product

High Speed 12V Power Tools With Lithium Battery

Product Description Power Source Electric Biggest drill hole 16mm Customized support OEM Application Industry Dimensions 32mm Hammering frequency 6200 Frequency 6200 MOQ 1PCS Max. […]

High Quality Multifunction Battery Powered Drill For Sale

Warranty 1 years Voltage 21V Place of Origin China Brand Name MSK Model Number MSK-PT Power Source LI-ION BATTERY No-Load Speed 1350prm Drilling Diameter 10mm Features 1. Strong to […]

Miter Saw Trim Panel Machine

Product Information Brand MSK Maximum Processing Thickness 80 (mm) Type Panel Saw Maximum Processing Width 1250 (mm) Forms Of Work Fully Automatic Total Weight 600 (kg) Rate […]

Power Tools Lithium Battery Power Drill Impact Drill

Product Information Brand MSK Power Type Rechargeable – Lithium Battery Technology Drill Holding Method Drill Chuck Forward And Reverse Direction About Scope Of Applic […]

Belt Machine Floor Sander

Product Information Brand MSK Sandpaper Size 110*100 Scope Of Application Woodworking, Sheet Metal Putty, Facade, Metal Derusting And Polishing Appendix Export Standard, Eur […]

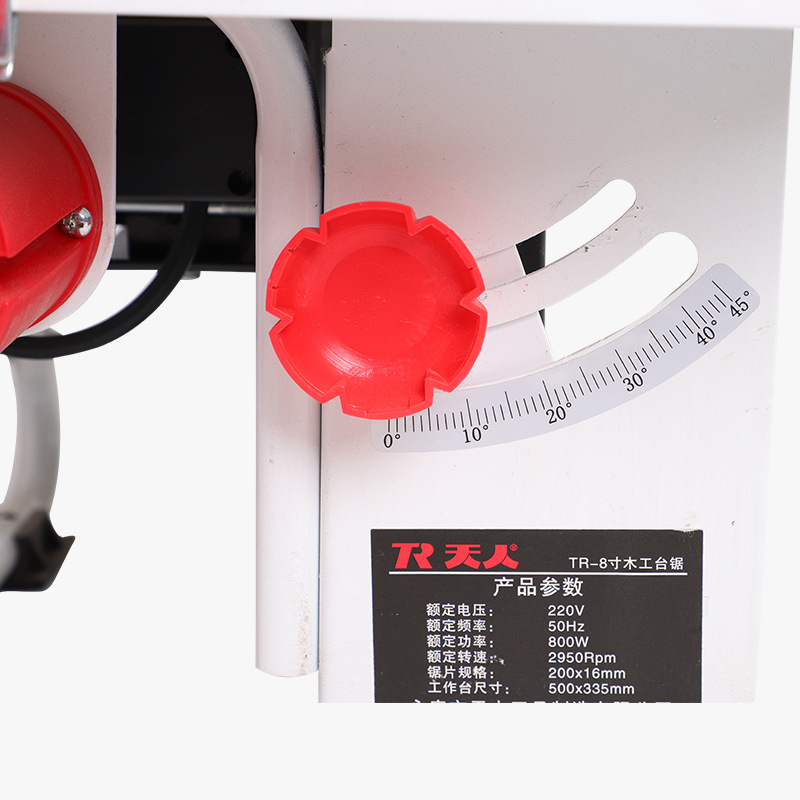

Woodworking Tools Woodworking Table Saw

Product Information Origin MSK Rated Voltage 220V Type Table Saw Scope Of Application Home Renovation Cutting Depth 45-27 (mm) Power Type AC Power Rated Input Power 800 (W) […]

Home Cutting Machine Hand Grinder Power Tools Grinder

Product Information Brand MSK Model Electric Angle Grinder Scope Of Application Cutting, Grinding Appendix Wrench, Carbon Brush Rated Voltage Range AC Single-Phase And DC 50 […]

Factory Wholesale High Pressure Water Gun Wireless Lithium Battery Car Wash Gun Charging Portable Car Wash Machine Brush Car Wash Machine

Product Information Brand MSK Work Pressure 30bar Material ABS Flow 3L/min Outlet Pipe Length 5 Meters Weight 2.5kg Power Cord Length Charger 1 Meter Power 180W/360W Power S […]

Wookworking Tool Electric Hand Planer

Product Information Brand MSK Power Type AC Power Power Cord Length 1.8 Rated Voltage Range AC Single-Phase And DC 50V Above 250V And Below Scope Of Application Carpentry Vo […]

Battery-powered Cordless Chainsaws

Product Information Brand MSK Voltage Twenty Four Battery Power 2000 Standard Accessories Guide Chain Scope Of Application Pruning, Logging, Cutting Power Type Rechargeable […]

Post time: 2023-06-28