Even without a deep knowledge on electrical tools, most of us use them on a daily basis for regular tasks. However, when extra work must be completed or failure occurs, a reliable comprehension of how to safely and precisely utilize these tools is key. Knowing how and when to use them appropriately is essential to increasing productivity and minimizing issues.

A deeper look into the essentials of electrical tools and the safety that must be observed in such work is presented here. Uncovering what each tool is used for and the risks associated so that one can equip themselves with the knowledge needed for a secure electrical job.

We can begin by discussing the fundamentals of electrical tools. These are items that utilize electric current to perform a specific function. Examples range from illuminating a lamp to managing a power saw. This energy is supplied by connecting the equipment to an electrical receptacle that is part of the electric circuit.

The average run-of-the-mill electrical tool used around the house taps into power supplied by a typical 120-volt outlet—pleasingly commonplace in the US. Conversely, fancier units like hairdryers and curling irons lean towards an outlet that gives off more oomph—240 volts, to be exact.

Before you put any electrical device to use, it is essential to verify that it is grounded completely. This means that the tool is connected to a rod which has been driven into the earth’s surface. This creates a pathway for any extra electric current to be diverted into the soil instead of through you.

To avoid the risk of electrocution, it is necessary to always keep tools properly grounded. If you come into contact with a live wire without this safety precaution, dire consequences could arise. Therefore, make sure to inspect the ground each time prior to plugging in a tool.

With a fundamental understanding of electricity and related gadgets in mind, let’s delve in and explore the various uses of some of the most prevalent items found in the toolbox of an electrician.

No matter what the application, the power drill is a trusted go-to tool when it comes to making holes. From wood and plastic to metal, the corded or cordless drill provides the perfect solution for a range of projects, with its reliable and efficient drilling capabilities.

An unlimited power supply is accessible when a corded power drill is plugged into an outlet, while portability is improved if a cordless drill with batteries is used, though it has a limited run time.

To start the process, power drills come with a squeezable trigger. Alternatively, there is a switch offered with the drill that will reverse the rotation of the drill bit – useful for taking out screws or fitting them into a material.

When selecting the right tool for a project, the size of the power drill you need will depend on the job ahead. The range of available sizes vary from compact, handheld units to beefy, stand-mounted designs.

Electrical saws equipped with the power to cut wood, plastic, and metal are a popular tool found in many workrooms. These devices appear in both plug-in or battery-powered variations.

In comparison to power drills, power saws that are of the corded variety require an outlet in order to be powered and have an inexhaustible energy source. Alternately, cordless power saws, which come equipped with batteries, provide portability but have more bounded periods of running time.

By squeezing the trigger, you can get most power saws going. With an extra flick of the switch, the direction of the blade can be swiftly reversed, proving to be especially useful when cutting in confined areas.

Projects come in all shapes and sizes, and therefore so do the power saws necessary to get the job done. From small handheld models for delicate works of art to larger, table-mounted units for heavy-duty jobs, having a wide selection of tools at your disposal is essential for crafting quality results.

For a smooth finish on hard-to-reach surfaces, a power sander is the ideal tool. These versatile workhorses are available with and without cords, and remove roughness from both wood and metal efficiently.

Those looking to tackle their sanding projects have two options: the corded power sander, connecting to a wall outlet for a constant power source, or the cordless version operating on a battery, albeit with a lessened deployment period.

All power sanders possess a conveniently-positioned trigger that must be briskly squeezed in order to activate the appliance. To top it off, an adjustable switch permits users to modify the angle of the sanding pad, enabling them to maneuver into small crevices or smoothly hone a curved surface.

Depending on your project, the power sander that you need must come in an appropriate size and style. Options range from handheld versions to full floor-coverage models.

Electric screwdrivers are the perfect tool for driving screws into nearly any surface. Whether corded or cordless, a power screwdriver is an invaluable addition to any toolbox. Mobile and reliable, these devices can handle a variety of screws and materials, from metal to wood.

An endless power source is offered when choosing a corded power screwdriver, but that comes with a tradeoff of portability. In contrast, a cordless model is more transportable due to their battery-operated design, but you’ll encounter limited running time.

Electric screwdrivers are commonly equipped with

Related Product

High Speed 12V Power Tools With Lithium Battery

Product Description Power Source Electric Biggest drill hole 16mm Customized support OEM Application Industry Dimensions 32mm Hammering frequency 6200 Frequency 6200 MOQ 1PCS Max. […]

High Quality Multifunction Battery Powered Drill For Sale

Warranty 1 years Voltage 21V Place of Origin China Brand Name MSK Model Number MSK-PT Power Source LI-ION BATTERY No-Load Speed 1350prm Drilling Diameter 10mm Features 1. Strong to […]

Miter Saw Trim Panel Machine

Product Information Brand MSK Maximum Processing Thickness 80 (mm) Type Panel Saw Maximum Processing Width 1250 (mm) Forms Of Work Fully Automatic Total Weight 600 (kg) Rate […]

Power Tools Lithium Battery Power Drill Impact Drill

Product Information Brand MSK Power Type Rechargeable – Lithium Battery Technology Drill Holding Method Drill Chuck Forward And Reverse Direction About Scope Of Applic […]

Belt Machine Floor Sander

Product Information Brand MSK Sandpaper Size 110*100 Scope Of Application Woodworking, Sheet Metal Putty, Facade, Metal Derusting And Polishing Appendix Export Standard, Eur […]

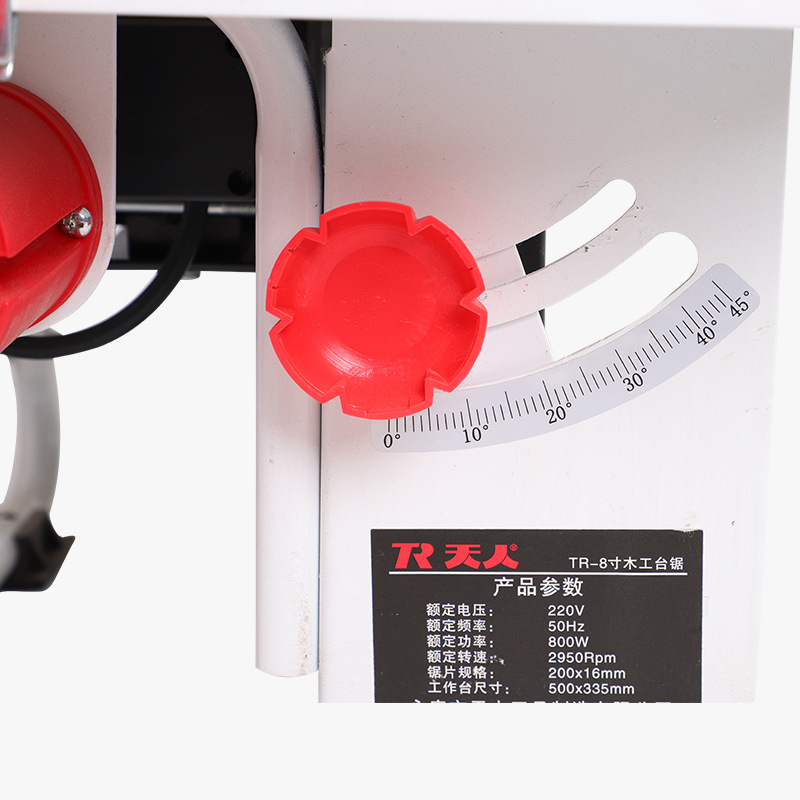

Woodworking Tools Woodworking Table Saw

Product Information Origin MSK Rated Voltage 220V Type Table Saw Scope Of Application Home Renovation Cutting Depth 45-27 (mm) Power Type AC Power Rated Input Power 800 (W) […]

Home Cutting Machine Hand Grinder Power Tools Grinder

Product Information Brand MSK Model Electric Angle Grinder Scope Of Application Cutting, Grinding Appendix Wrench, Carbon Brush Rated Voltage Range AC Single-Phase And DC 50 […]

Factory Wholesale High Pressure Water Gun Wireless Lithium Battery Car Wash Gun Charging Portable Car Wash Machine Brush Car Wash Machine

Product Information Brand MSK Work Pressure 30bar Material ABS Flow 3L/min Outlet Pipe Length 5 Meters Weight 2.5kg Power Cord Length Charger 1 Meter Power 180W/360W Power S […]

Wookworking Tool Electric Hand Planer

Product Information Brand MSK Power Type AC Power Power Cord Length 1.8 Rated Voltage Range AC Single-Phase And DC 50V Above 250V And Below Scope Of Application Carpentry Vo […]

Battery-powered Cordless Chainsaws

Product Information Brand MSK Voltage Twenty Four Battery Power 2000 Standard Accessories Guide Chain Scope Of Application Pruning, Logging, Cutting Power Type Rechargeable […]

Post time: 2023-06-23