Carved into any general handyman’s toolkit, the angle grinder is specifically designed for a wide range of domestic and industrial purposes. Although renowned for its metal-grinding prowess, this readily available power tool can also be used for cutting, sanding and polishing all manner of surfaces. Moreover, by attaching the appropriate components to the grinder, DIY enthusiasts are able to reap rewards beyond expectations by whipping into shape metal railings, refining flagstone tiles or honing garden shears with minimal fuss.

If you want to safely and effectively use an angle grinder, you first need to become familiar with its operation and the preventative measures to take. Here is a helpful overview that will give you an idea of how to use an angle grinder, as well as tricks to get the most out of it.

Mastering the Angle Grinder: Essential Tips and Techniques

Before you set to work with your angle grinder, knowing the hazards and taking safety precautions should be your top priority. Neglecting to do so can put you at serious risk, so make sure you’re constantly aware of the potential danger that comes with operating this tool.

Outfitted to Ensure Safety

To keep your eyes, mouth, hands, and lungs safe when working with an angle grinder, be sure to grab a pair of safety goggles or glasses, a dust mask, and some gloves before beginning. This will help you safeguard yourself from inhaling any dangerous particles and prevent the tool’s abrasive wheel from harming your hands.

If you’re going to be working with metal, shielding your arms from any potential sparks is a great idea. Therefore, it is wise to wear a shirt with long sleeves.

Assessing the Abrasive Disc

Before powering your angle grinder, inspect the grinding wheel for any visible damage such as cracks, nicks or any other flaws. Should even the slightest imperfection present itself, refrain from using it and replace it with a fresh, undamaged wheel.

You must ensure that the grinding wheel employed is suitable for the material to be processed; for example, don’t make the mistake of opting for a grinding wheel crafted for metal when the job entails grinding concrete.

Unsure of which grinding wheel would be best? Look no further than the angle grinder’s manual or head down to your local go-to for home improvement needs and engage a sales representative, they’ll have the know-how to help you find the perfect wheel.

Navigating the Maze of Angle Grinders

The capabilities of angle grinders can vastly differ based on the model; from their size to their speed and power.

If you are carrying out work predominantly around the house, a 4-inch angle grinder should meet all your needs. On the other hand, for more robust tasks, it is advisable to invest in a more substantial and powerful device.

The rotational revolutions of the angle grinder are counted in rpm (per minute). An elevated rpm indicates that the grinding wheel is accelerating quickly.

To tackle commonplace home projects, an angle grinder operating at a speed between 10,000 to 11,000 rpm is ample. If however, you’re engaging in a more demanding venture, selecting a device with higher revolutions per minute is recommended.

When looking to assess how powerful an angle grinder is, amps are the metric to turn to. The more amps the device has, the more heavy-duty jobs it can take on. Typically, an angle grinder with 4 amps is enough for those pesky domestic projects. However, for a bigger workload, you’ll likely need to increase your amp rating.

Harness the Power of the Angle Grinder

After making your choice for the most suitable angle grinder, you are ready to begin. Secure the implement firmly in both hands and place the grinding wheel onto the material you are looking to modify.

After powering up your angle grinder, give the grinding wheel a gentle nudge as it meets the material. This will help you get a head-start on the job and get the most out of the grinder.

When manipulating metal with an angle grinder, you may have to put more force into the device. However, applying too much pressure for other sorts of projects can result in smashing of the material or causing the grinding disk to shatter.

To avoid tension on the grinding wheel, alleviate the force temporarily, allowing the hunk of metal to spin unrestrainedly for a short amount of time prior to exerting tension anew.

Unleash Energy From Within

Once you’ve completed your work with the angle grinder, disengage the power switch to turn off the tool. Then, place the tool on an even area and pause for the grinding wheel to finish revolving before relocating it.

Put an Angle Grinder to Work: Versatile Tool Uses in the Home and Workshop

Taking the time to understand the basic functioning of an angle grinder can undoubtedly have its payoff. There is a broad range of potential projects that this tool can be utilized for, just a few of which include:

To free metal surfaces from rust, paint, or other blemishes, an angle grinder with a specialized grinding wheel can provide the perfect solution. By applying just the correct amount of pressure and force, old metal surfaces can be smoothed and revitalized.

Related Product

High Speed 12V Power Tools With Lithium Battery

Product Description Power Source Electric Biggest drill hole 16mm Customized support OEM Application Industry Dimensions 32mm Hammering frequency 6200 Frequency 6200 MOQ 1PCS Max. […]

High Quality Multifunction Battery Powered Drill For Sale

Warranty 1 years Voltage 21V Place of Origin China Brand Name MSK Model Number MSK-PT Power Source LI-ION BATTERY No-Load Speed 1350prm Drilling Diameter 10mm Features 1. Strong to […]

Miter Saw Trim Panel Machine

Product Information Brand MSK Maximum Processing Thickness 80 (mm) Type Panel Saw Maximum Processing Width 1250 (mm) Forms Of Work Fully Automatic Total Weight 600 (kg) Rate […]

Power Tools Lithium Battery Power Drill Impact Drill

Product Information Brand MSK Power Type Rechargeable – Lithium Battery Technology Drill Holding Method Drill Chuck Forward And Reverse Direction About Scope Of Applic […]

Belt Machine Floor Sander

Product Information Brand MSK Sandpaper Size 110*100 Scope Of Application Woodworking, Sheet Metal Putty, Facade, Metal Derusting And Polishing Appendix Export Standard, Eur […]

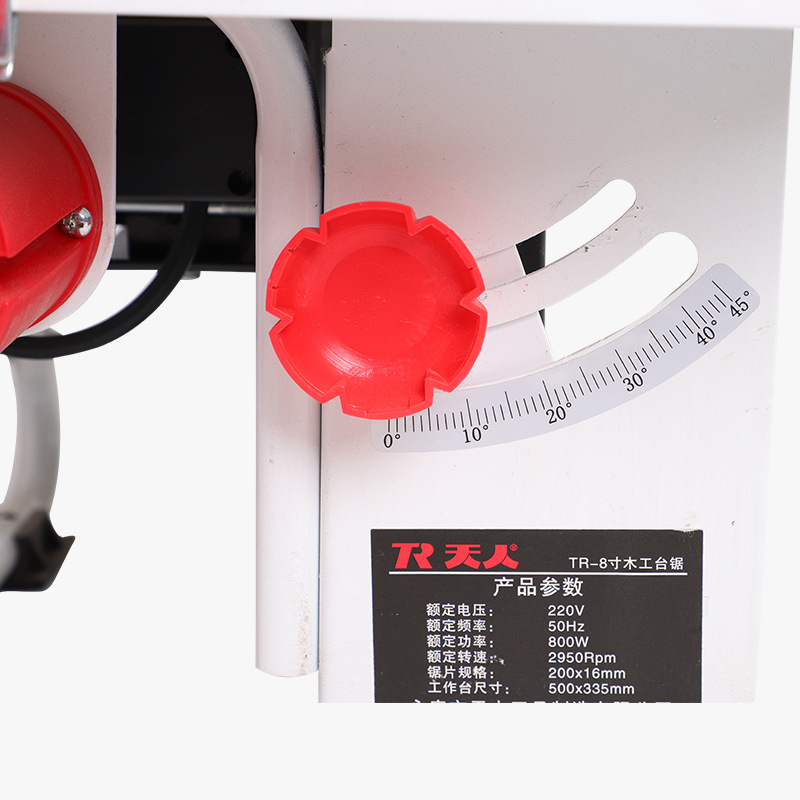

Woodworking Tools Woodworking Table Saw

Product Information Origin MSK Rated Voltage 220V Type Table Saw Scope Of Application Home Renovation Cutting Depth 45-27 (mm) Power Type AC Power Rated Input Power 800 (W) […]

Home Cutting Machine Hand Grinder Power Tools Grinder

Product Information Brand MSK Model Electric Angle Grinder Scope Of Application Cutting, Grinding Appendix Wrench, Carbon Brush Rated Voltage Range AC Single-Phase And DC 50 […]

Factory Wholesale High Pressure Water Gun Wireless Lithium Battery Car Wash Gun Charging Portable Car Wash Machine Brush Car Wash Machine

Product Information Brand MSK Work Pressure 30bar Material ABS Flow 3L/min Outlet Pipe Length 5 Meters Weight 2.5kg Power Cord Length Charger 1 Meter Power 180W/360W Power S […]

Wookworking Tool Electric Hand Planer

Product Information Brand MSK Power Type AC Power Power Cord Length 1.8 Rated Voltage Range AC Single-Phase And DC 50V Above 250V And Below Scope Of Application Carpentry Vo […]

Battery-powered Cordless Chainsaws

Product Information Brand MSK Voltage Twenty Four Battery Power 2000 Standard Accessories Guide Chain Scope Of Application Pruning, Logging, Cutting Power Type Rechargeable […]

Post time: 2023-06-09