Hydraulic tools are an instrumental part of industrial or construction work that often involves heavy lifting. Utilizing the hydraulic power, these tools enable a vast range of tasks to be completed with accuracy and ease, including lifting, pressing, and cutting.

Running on hydraulic pressure, tools of this type draw their energy from a specialized pump that pumps either oil, water, or air. This pressure-generating device is combined with a power source like an electric motor to supply sufficient power and enable the tool’s operation.

Hydraulic tools are commonplace, and the most widespread is the hydraulic jack. By attaching a hose to connect the hydraulic pump to the jack, a simple switch can activate and boost pressure so that heavy objects are lifted.

Hydraulic jacks are often employed in lifting a broad range of objects such as cars, trucks, and trailers; though they can just as easily provide their powerful service when it comes to raising heavier objects, such as excavators and loaders.

Hydraulic presses serve as an integral type of hydraulic tool, utilized to press or stamp various objects. Upon activation of a switch, the pressure produced by the connected pump will compact the object accordingly. Thus, a durable hose is essential in linking the press to its appropriated pump.

The power of a hydraulic press finds manifold uses; from providing force to metal sheets to form intricate shapes and designs through stamping, to pressing car parts and bearings into various mechanical fixtures.

An alternative form of hydraulic tool is the hydraulic cutter, a device utilized to slice or sever items. It is attached to the hydraulic pump with a hose, which is then engaged by the twist of a switch. Provisioned with pressure from the pump, the machine cuts through whatever lies before it.

Hydraulic cutters are immensely useful tools for a myriad of projects, such as slicing through steel sheets and pipes. Not only that, but with the right settings, these cutters can also cut effortlessly through concrete and asphalt.

A plethora of sizes and styles of hydraulic pumps are available for purchase, though the most commonly employed type is the hand pump. This type of pump makes use of a handle for its operation, allowing you to pump oil into the hydraulic system without breaking a sweat.

With its handheld and lightweight design, the hand pump is a popular choice among hydraulic pumps, especially when it comes to cost. Its portability adds an extra layer of convenience, making it the go-to option for many users.

An electric motor ignites the functionality of the electric hydraulic pump, which pumps oil and sends it throughout the hydraulic system. This type of pump is used to operate hydraulic machinery.

The electric hydraulic pump is a pricey piece of equipment, but its strength surpasses that of the hand pump. Not to mention, it offers an added layer of convenience, as it can be operated without a pump handle.

An air hydraulic pump is an essential system designed to deliver oil through a compressor. When activated, the air-powered mechanism works to pump oil into the requisite hydraulic system.

When it comes to choosing between hydraulic pumps, the air-powered option stands out due to its superior strength – albeit at the cost of a higher sum. Additionally, with no need for manual cranking, it is more user-friendly than either hand or electric models.

For tasks that require a great deal of force, hydraulic tools are a reliable and efficient solution. Powered by fluid pressure, these tools have numerous applications in the construction and industrial industries, enabling users to lift, press, and slice with ease. Their versatility makes them a valuable asset for any arduous job.

Related Product

High Speed 12V Power Tools With Lithium Battery

Product Description Power Source Electric Biggest drill hole 16mm Customized support OEM Application Industry Dimensions 32mm Hammering frequency 6200 Frequency 6200 MOQ 1PCS Max. […]

High Quality Multifunction Battery Powered Drill For Sale

Warranty 1 years Voltage 21V Place of Origin China Brand Name MSK Model Number MSK-PT Power Source LI-ION BATTERY No-Load Speed 1350prm Drilling Diameter 10mm Features 1. Strong to […]

Miter Saw Trim Panel Machine

Product Information Brand MSK Maximum Processing Thickness 80 (mm) Type Panel Saw Maximum Processing Width 1250 (mm) Forms Of Work Fully Automatic Total Weight 600 (kg) Rate […]

Power Tools Lithium Battery Power Drill Impact Drill

Product Information Brand MSK Power Type Rechargeable – Lithium Battery Technology Drill Holding Method Drill Chuck Forward And Reverse Direction About Scope Of Applic […]

Belt Machine Floor Sander

Product Information Brand MSK Sandpaper Size 110*100 Scope Of Application Woodworking, Sheet Metal Putty, Facade, Metal Derusting And Polishing Appendix Export Standard, Eur […]

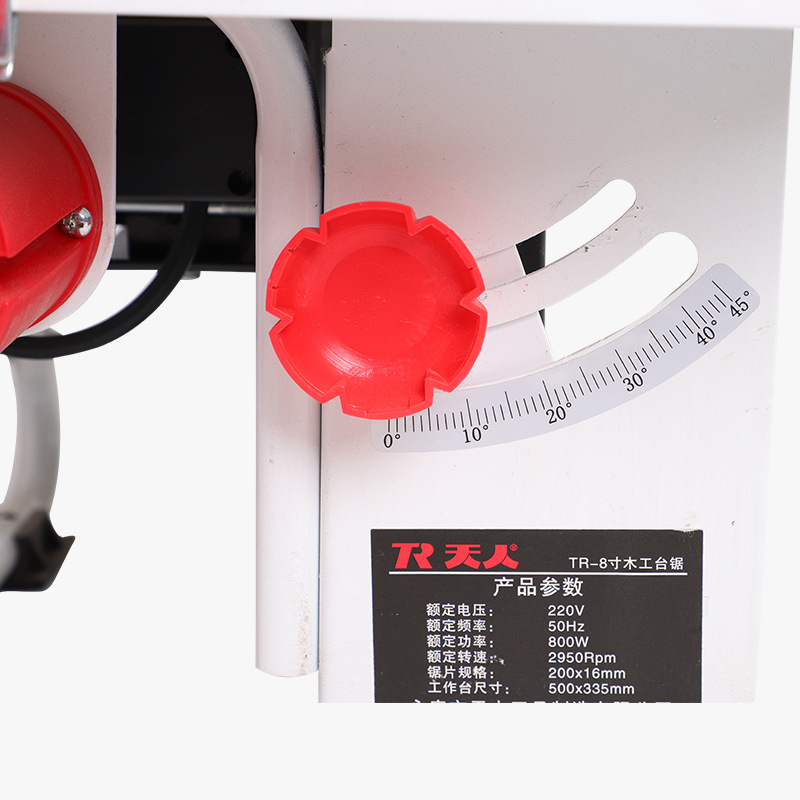

Woodworking Tools Woodworking Table Saw

Product Information Origin MSK Rated Voltage 220V Type Table Saw Scope Of Application Home Renovation Cutting Depth 45-27 (mm) Power Type AC Power Rated Input Power 800 (W) […]

Home Cutting Machine Hand Grinder Power Tools Grinder

Product Information Brand MSK Model Electric Angle Grinder Scope Of Application Cutting, Grinding Appendix Wrench, Carbon Brush Rated Voltage Range AC Single-Phase And DC 50 […]

Factory Wholesale High Pressure Water Gun Wireless Lithium Battery Car Wash Gun Charging Portable Car Wash Machine Brush Car Wash Machine

Product Information Brand MSK Work Pressure 30bar Material ABS Flow 3L/min Outlet Pipe Length 5 Meters Weight 2.5kg Power Cord Length Charger 1 Meter Power 180W/360W Power S […]

Wookworking Tool Electric Hand Planer

Product Information Brand MSK Power Type AC Power Power Cord Length 1.8 Rated Voltage Range AC Single-Phase And DC 50V Above 250V And Below Scope Of Application Carpentry Vo […]

Battery-powered Cordless Chainsaws

Product Information Brand MSK Voltage Twenty Four Battery Power 2000 Standard Accessories Guide Chain Scope Of Application Pruning, Logging, Cutting Power Type Rechargeable […]

Post time: 2023-06-26