Although there are many different brands and models of chainsaws, their structures are similar, and they are all in line with ergonomic design principles.

Chain brake – also known as brake, a device used to quickly stop the rotation of the chain, mostly used for chain saw braking in emergency situations, and is one of the safety functions.

Saw chain gear—also known as sprocket, is used to drive the toothed parts of the saw chain; its wear and tear must be checked before use and replaced in time.

Front Handle – The handle installed on the front of the chainsaw, also known as the side handle. Front handle baffle – also known as safety baffle, a structural barrier installed in front of the chain saw’s front handle and guide plate, mostly installed near the front handle, and sometimes used as the operating lever of the chain brake. It is one of the safety features.

Guide plate – also known as chain plate, a solid track structure, used to support and conduct the saw chain; before use, check the wear of the guide groove, repair it in time, and replace it if necessary.

Oil pump – manual or automatic pump oil, used to refuel the guide plate and saw chain; check its oil supply before use, adjust the oil supply in time, and replace it in time if the damage is serious.

Rear Handle – The handle mounted on the rear of the chain saw and is part of the main handle.

Saw chain—a chain with teeth for cutting wood, installed on the guide plate; check its wear and tear before use, repair files in time, check its tension, and adjust it in time.

Related Product

High Speed 12V Power Tools With Lithium Battery

Product Description Power Source Electric Biggest drill hole 16mm Customized support OEM Application Industry Dimensions 32mm Hammering frequency 6200 Frequency 6200 MOQ 1PCS Max. […]

High Quality Multifunction Battery Powered Drill For Sale

Warranty 1 years Voltage 21V Place of Origin China Brand Name MSK Model Number MSK-PT Power Source LI-ION BATTERY No-Load Speed 1350prm Drilling Diameter 10mm Features 1. Strong to […]

Miter Saw Trim Panel Machine

Product Information Brand MSK Maximum Processing Thickness 80 (mm) Type Panel Saw Maximum Processing Width 1250 (mm) Forms Of Work Fully Automatic Total Weight 600 (kg) Rate […]

Power Tools Lithium Battery Power Drill Impact Drill

Product Information Brand MSK Power Type Rechargeable – Lithium Battery Technology Drill Holding Method Drill Chuck Forward And Reverse Direction About Scope Of Applic […]

Belt Machine Floor Sander

Product Information Brand MSK Sandpaper Size 110*100 Scope Of Application Woodworking, Sheet Metal Putty, Facade, Metal Derusting And Polishing Appendix Export Standard, Eur […]

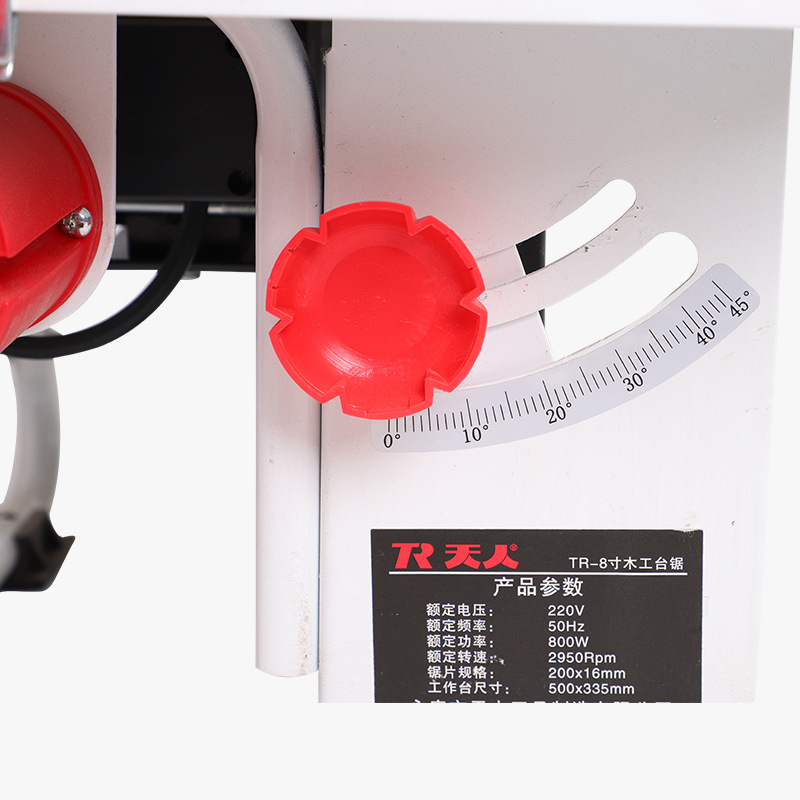

Woodworking Tools Woodworking Table Saw

Product Information Origin MSK Rated Voltage 220V Type Table Saw Scope Of Application Home Renovation Cutting Depth 45-27 (mm) Power Type AC Power Rated Input Power 800 (W) […]

Home Cutting Machine Hand Grinder Power Tools Grinder

Product Information Brand MSK Model Electric Angle Grinder Scope Of Application Cutting, Grinding Appendix Wrench, Carbon Brush Rated Voltage Range AC Single-Phase And DC 50 […]

Factory Wholesale High Pressure Water Gun Wireless Lithium Battery Car Wash Gun Charging Portable Car Wash Machine Brush Car Wash Machine

Product Information Brand MSK Work Pressure 30bar Material ABS Flow 3L/min Outlet Pipe Length 5 Meters Weight 2.5kg Power Cord Length Charger 1 Meter Power 180W/360W Power S […]

Wookworking Tool Electric Hand Planer

Product Information Brand MSK Power Type AC Power Power Cord Length 1.8 Rated Voltage Range AC Single-Phase And DC 50V Above 250V And Below Scope Of Application Carpentry Vo […]

Battery-powered Cordless Chainsaws

Product Information Brand MSK Voltage Twenty Four Battery Power 2000 Standard Accessories Guide Chain Scope Of Application Pruning, Logging, Cutting Power Type Rechargeable […]

Post time: 2022-05-11