As climate consciousness continues to spread amongst the populous, the need for a safe, cost-effective and efficient way to flare combustible gases such as natural gas has become integral. Non-electric flaring methods can be a dangerous and costly venture, but with the introduction of electrical flaring tools, the flaring procedure is now much safer, convenient and affordable.

Electric flaring tools have been designed to take combustible gases and transform them into combustible vapors which can be serviced in an orderly and secure fashion. In addition, the electric flaring tool produces a noticeable and safe flame with no hazardous by-products. This apparatus is employed in a broad range of sectors, ranging from oil and gas to production and engineering.

Electric flaring tools provide a cost-effective, efficient answer for flaring natural gas and other combustible gases. Compared to traditional flares, these tools require much less energy for optimal performance, resulting in cost savings for the user as the task can be completed quicker. Additionally, supplementary safety comes with using electric flaring tools opposed to traditional flaring methods due to their lack of potentially hazardous by-products.

Utilizing an electric flaring tool is definitely the way to go instead of relying on traditional methods. You don’t need to be a tech guru to operate one – it’s user-friendly and requires little effort to get going and keep it well-maintained. Plus, with its reliable and resilient structure, you can rest assured that your electric flaring tool will carry out all its tasks with excellence for a long duration.

When flare work is needed, electric flares are the ultimate go-to. Their versatility allows them to be utilized in industries ranging from oil and gas to fabrication and construction, as well as in indoor or outdoor environments. No matter the task at hand or the setting, electric flaring tools prove to be a practical solution.

Taking into account its efficacious and cost-effective flare-up, it’s no wonder electric flaring tools are soaring in popularity for those needing to flare natural gas and other combustible gases. Not only are these gadgets simpler to utilize and keep up with than conventional flaring processes, but they make it incredibly secure too. In sum, electric flaring tools have all of the rewards one could ask for – making them a no-brainer for anyone seeking an uncomplicated, cost-effective, and safe alternative.

Unlocking the Potential of Electric Flaring Tools in Manufacturing Industries

In industrial settings, flaring tools have been an essential tool for a wide selection of tasks such as cutting, bending, and connecting pipes. Over time, these tools have found increased relevance as the industrial sphere has become more intricate. Among the wide array of flaring tools, electric tools are particularly well-liked, due to the distinct advantages they offer that have made them an increasingly popular choice.

Electric flaring tools present many advantages over their traditional counterparts. Perhaps most notably, they are free of the potential danger that comes with using air or hydraulic pressure — no escaping pressure means no risk of injury. Additionally, these tools offer higher levels of precision and efficiency, making them an ideal choice for tasks that require exactness and accuracy.

Electric flaring tools boast a major advantage due to their light weight, enabling for effortless transportation and utilization in countless contexts. Moreover, these instruments’ multi-faceted operations, enhanced to perform multiple operations at once, can provide a huge cost and time efficiency – most notably when it comes to cutting and bending pipes in unison.

For those who are operating on a budget but need to get the job done, electric flaring tools make an ideal choice. Not only are they often much more affordable than traditional models, they also reduce costs associated with upkeep as they do not require as much maintenance.

Electric flaring tools offer unbeatable advantages, making them the go-to choice for any job requiring an efficient, precise result. Even on a tight budget, you can benefit from their affordability as well as their easy maintenance and transportation. Traditional models simply can’t compete with electric flaring tools’ sheer levels of convenience and safety; consequently, they continue to become ever more sought-after in industrial settings, where speed and accuracy are of the utmost importance.

Related Product

High Speed 12V Power Tools With Lithium Battery

Product Description Power Source Electric Biggest drill hole 16mm Customized support OEM Application Industry Dimensions 32mm Hammering frequency 6200 Frequency 6200 MOQ 1PCS Max. […]

High Quality Multifunction Battery Powered Drill For Sale

Warranty 1 years Voltage 21V Place of Origin China Brand Name MSK Model Number MSK-PT Power Source LI-ION BATTERY No-Load Speed 1350prm Drilling Diameter 10mm Features 1. Strong to […]

Miter Saw Trim Panel Machine

Product Information Brand MSK Maximum Processing Thickness 80 (mm) Type Panel Saw Maximum Processing Width 1250 (mm) Forms Of Work Fully Automatic Total Weight 600 (kg) Rate […]

Power Tools Lithium Battery Power Drill Impact Drill

Product Information Brand MSK Power Type Rechargeable – Lithium Battery Technology Drill Holding Method Drill Chuck Forward And Reverse Direction About Scope Of Applic […]

Belt Machine Floor Sander

Product Information Brand MSK Sandpaper Size 110*100 Scope Of Application Woodworking, Sheet Metal Putty, Facade, Metal Derusting And Polishing Appendix Export Standard, Eur […]

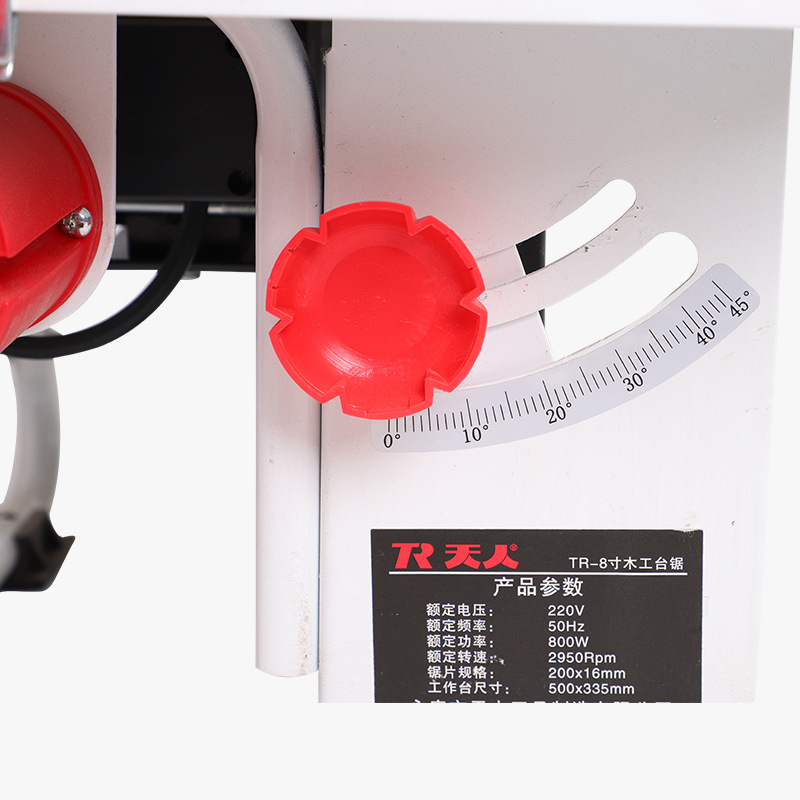

Woodworking Tools Woodworking Table Saw

Product Information Origin MSK Rated Voltage 220V Type Table Saw Scope Of Application Home Renovation Cutting Depth 45-27 (mm) Power Type AC Power Rated Input Power 800 (W) […]

Home Cutting Machine Hand Grinder Power Tools Grinder

Product Information Brand MSK Model Electric Angle Grinder Scope Of Application Cutting, Grinding Appendix Wrench, Carbon Brush Rated Voltage Range AC Single-Phase And DC 50 […]

Factory Wholesale High Pressure Water Gun Wireless Lithium Battery Car Wash Gun Charging Portable Car Wash Machine Brush Car Wash Machine

Product Information Brand MSK Work Pressure 30bar Material ABS Flow 3L/min Outlet Pipe Length 5 Meters Weight 2.5kg Power Cord Length Charger 1 Meter Power 180W/360W Power S […]

Wookworking Tool Electric Hand Planer

Product Information Brand MSK Power Type AC Power Power Cord Length 1.8 Rated Voltage Range AC Single-Phase And DC 50V Above 250V And Below Scope Of Application Carpentry Vo […]

Battery-powered Cordless Chainsaws

Product Information Brand MSK Voltage Twenty Four Battery Power 2000 Standard Accessories Guide Chain Scope Of Application Pruning, Logging, Cutting Power Type Rechargeable […]

Post time: 2023-07-05