Forging metallic objects requires powerful levels of force, which is why a power press is usually used. This type of machine functions by providing pressure to shape and form metals, with variants that differ based on the way in which the applied force works, its direction of movement, and the number of rams present.

Thanks to a power press, metal can be quickly and precisely hammered into desired dimensions. This is due to the vast amounts of force this machinery is able to generate, which is distributed evenly over a large surface area.

From large-scale hydraulic presses to tabletop presses, there are a myriad of different types of power presses. Each possesses its own strengths and weaknesses, however the most popular is the hydraulic press which utilizes hydraulic fluid to develop great strength.

Despite their strength and massive amount of force-producing capabilities, hydraulic presses come with a hefty price tag and demand a considerable amount of caution during upkeep.

Whereas hydraulic presses rely on hydraulics for power, mechanical presses employ a clever use of cams and levers to create force. This makes them budget-friendly and relatively low-maintenance compared to their hydraulic counterparts – although not as powerful – giving users an alternative option when deciding between the two.

Pneumatic presses are the most economical and least labor-intensive option when it comes to selecting a press type. Powered by compressed air, these presses lack the force of their mechanical and hydraulic counterparts but carry with them a lower price point and the benefit of simplified upkeep.

When making a choice in regard to press, it is critical to take into consideration the specific purpose of the application. In other words, if you require a heavy-duty operation, you must ensure to choose a press with more strength.

When deciding what type of power drill to use on metal workpieces, various components need to be consulted. For starters, consider the dimensions of the piece, as well as the grade of metal used for the task.

It is crucial to consider the size and the speed of the drill required to create a precise hole.

The rate at which the drill bit advances through the material is the fifth factor to consider; it determines how fast it penetrates. The sixth factor is the extent that the hole must be punched into the metal.

Selecting a drill bit will require you to consider the seventh variety, while the subsequent option is that of coolant, which must be employed to ensure that said basis of drilling remains sufficiently chilled.

To successfully utilize the press, you must secure the ninth power source and uphold the tenth safety guidelines. Operating the press requisites a reliable energy source and must be executed cautiously to restrict potential harm.

Doing your homework before settling on a power press for drilling holes in metal pays off. With a number of brand options available, it’s worth taking the time to evaluate which one best fits the job at hand. Scrutinizing the market will set you up for success when finding just the press you need.

As soon as you locate the optimal press, you can effortlessly undertake the process of metal-drilling.

Related Product

High Speed 12V Power Tools With Lithium Battery

Product Description Power Source Electric Biggest drill hole 16mm Customized support OEM Application Industry Dimensions 32mm Hammering frequency 6200 Frequency 6200 MOQ 1PCS Max. […]

High Quality Multifunction Battery Powered Drill For Sale

Warranty 1 years Voltage 21V Place of Origin China Brand Name MSK Model Number MSK-PT Power Source LI-ION BATTERY No-Load Speed 1350prm Drilling Diameter 10mm Features 1. Strong to […]

Miter Saw Trim Panel Machine

Product Information Brand MSK Maximum Processing Thickness 80 (mm) Type Panel Saw Maximum Processing Width 1250 (mm) Forms Of Work Fully Automatic Total Weight 600 (kg) Rate […]

Power Tools Lithium Battery Power Drill Impact Drill

Product Information Brand MSK Power Type Rechargeable – Lithium Battery Technology Drill Holding Method Drill Chuck Forward And Reverse Direction About Scope Of Applic […]

Belt Machine Floor Sander

Product Information Brand MSK Sandpaper Size 110*100 Scope Of Application Woodworking, Sheet Metal Putty, Facade, Metal Derusting And Polishing Appendix Export Standard, Eur […]

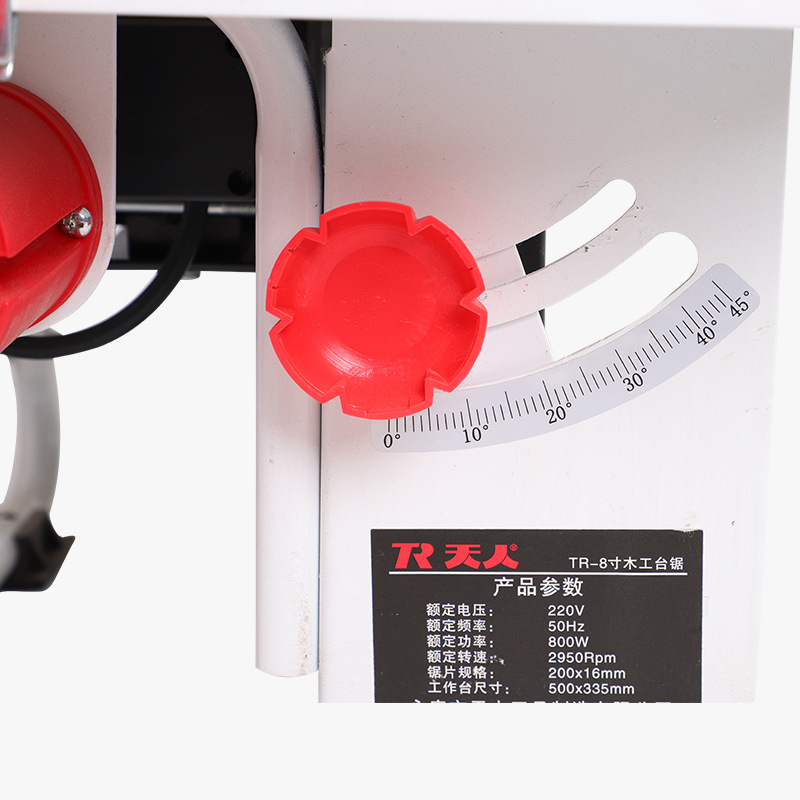

Woodworking Tools Woodworking Table Saw

Product Information Origin MSK Rated Voltage 220V Type Table Saw Scope Of Application Home Renovation Cutting Depth 45-27 (mm) Power Type AC Power Rated Input Power 800 (W) […]

Home Cutting Machine Hand Grinder Power Tools Grinder

Product Information Brand MSK Model Electric Angle Grinder Scope Of Application Cutting, Grinding Appendix Wrench, Carbon Brush Rated Voltage Range AC Single-Phase And DC 50 […]

Factory Wholesale High Pressure Water Gun Wireless Lithium Battery Car Wash Gun Charging Portable Car Wash Machine Brush Car Wash Machine

Product Information Brand MSK Work Pressure 30bar Material ABS Flow 3L/min Outlet Pipe Length 5 Meters Weight 2.5kg Power Cord Length Charger 1 Meter Power 180W/360W Power S […]

Wookworking Tool Electric Hand Planer

Product Information Brand MSK Power Type AC Power Power Cord Length 1.8 Rated Voltage Range AC Single-Phase And DC 50V Above 250V And Below Scope Of Application Carpentry Vo […]

Battery-powered Cordless Chainsaws

Product Information Brand MSK Voltage Twenty Four Battery Power 2000 Standard Accessories Guide Chain Scope Of Application Pruning, Logging, Cutting Power Type Rechargeable […]

Post time: 2023-06-25